Technological Methods

Our state-of-the-art laboratory is meticulously outfitted to offer comprehensive technological solutions in the dynamic realm of bioplastics and biopolymers. Our equipment and expert team ensure precise examination and evaluation, enabling us to delve deep into the properties and characteristics of sustainable materials.

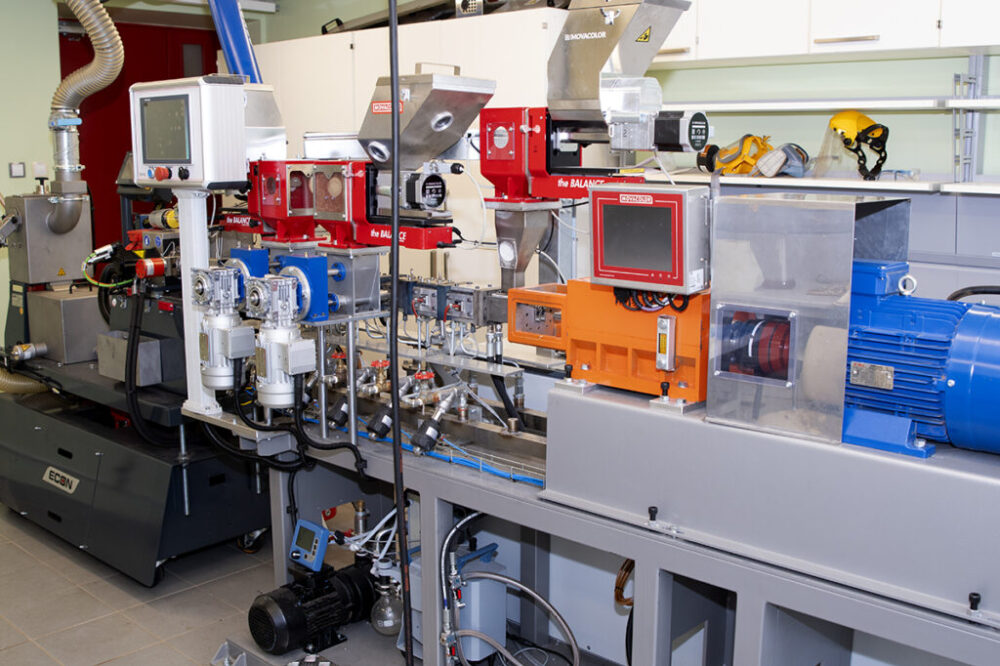

Collin Teach Line E 20 T + BL 50 T

Film blowing line: Screw diameter 20 mm, L/D ratio 25, max. 300°C, 400 bar, circular die diameter 30 mm, max. bubble diameter 110 mm.

Eur.Ex.Ma E-LAB22 + Econ EUP 10

Twin screw co-rotating compounding and reactive extrusion line with underwater pelletizer: screw diameter 21.7 mm, L/D ratio 40, max. rotation speed 600 rpm, main motor 7.5 kW, working temperature up to 300°C, max.

productivity 15 kg/h, gravimetric feeding and two gravimetric sidefeeders, liquids feeding, degassing. The line is equipped with an underwater pelletizer.

Thermo Scientific HAAKE MiniCTW

Twin screw co-rotating minicompounder: 4 – 15 mm conical screws, max. 360 rpm, max. 300°C, max. torque 5 Nm, mixing batch ~10 g.

Brabender Plasti-Corder PLE 651 + DSK 42/7

Twin screw counter-rotating compounding line: screw diameter 41.8 mm, L/D ratio 7, max. 300°C, max. torque 300 Nm, max 150 bar. Air-cooled pelletizing line. Max. productivity ~1 kg/h.

Arburg Allrounder 270S

Injection moulding of ISO 572-2 type 1A universal test specimen by hot runner mould. Screw dia. 18 mm, L/D ratio 14.5, injection volume 15.3 cm, clamping force 250 kN.

Babyplast 610 P

Injection moulding of ISO 572-2 type 1BB test specimen by cold runner mould. Piston dia. 14 mm, injection volume 9 cm, clamping force 62.5 kN.

Battenfeld BA 230E

Injection moulding of ISO 572-2 type 1A universal test specimen by cold runner mould. Screw dia. 25 mm, L/D ratio 16, injection volume 30.4 cm, clamping force 230 kN.

SCAMIA Modulaire U.03 MP

Calander: cylinder diameter 100 mm, useful length 220 mm, max. rotation speed 30 rpm, max. 300°C, 50 – 200 g mixing batches.

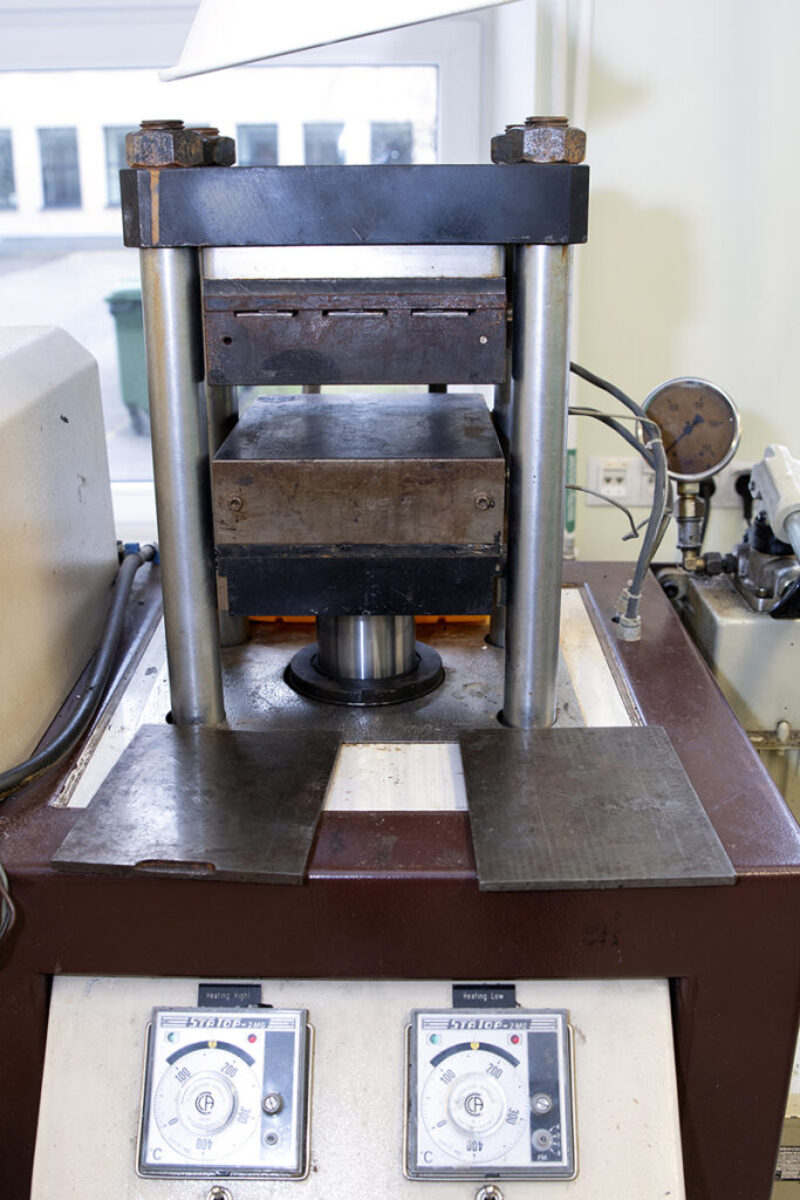

SCAMIA Modulaire U.03 MP

Hot press: dimension of the plates 200 x 200 mm, piston stroke 200 mm, max. 300°C, max. closing force 100 kN.

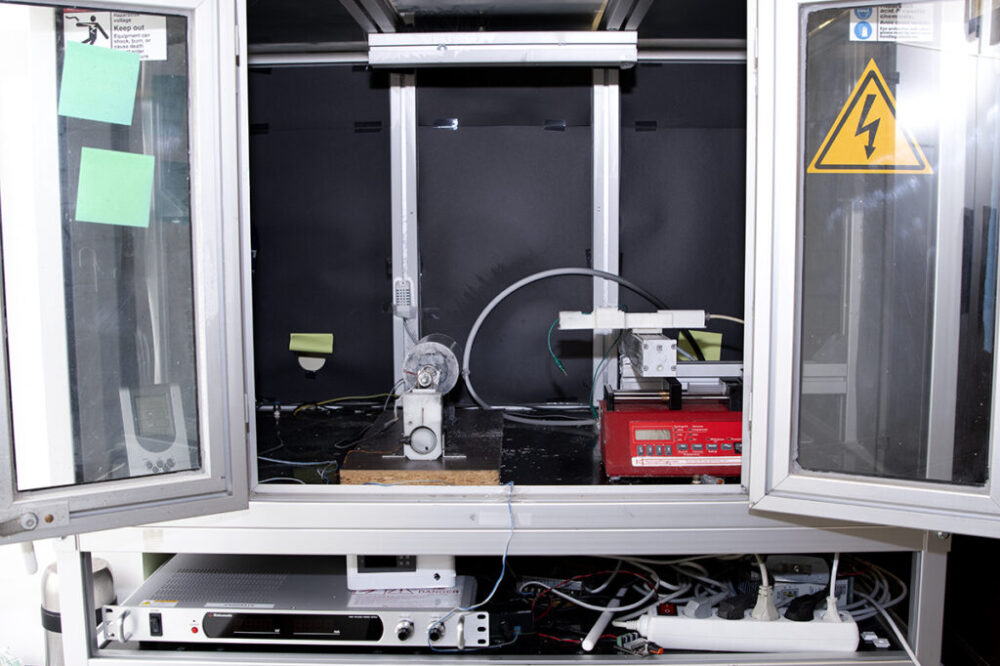

Elmarco Nanospider NS LAB

Laboratory pilot electrospinning, moving carriage with a rigid spinning electrode: max. line speed 5000 mm/min, useful with 400 mm, max. voltage 80 kV, electrode distance range 124 – 240 mm. max. volume of electrospinning solution 40 ml per batch, run time 30 – 80 min. per batch.

In-house built original equipment

Laboratory, syringe needle-based electrospinning setup with a rotating drum collector and linear actuator for the syringe.

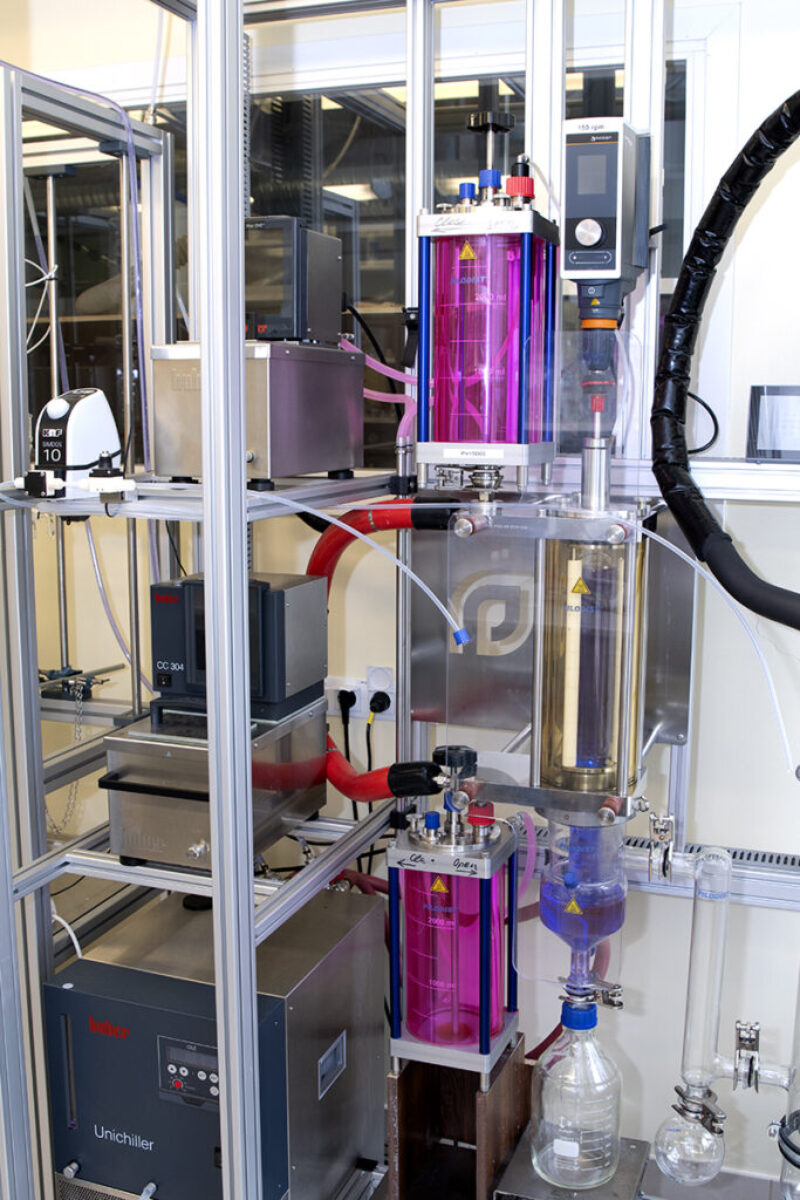

Combined distillation setup using HWS glassware

Setup for distillation of ~1 liter of liquid with a high boiling point up to 230°C in a vacuum. Separation of two fractions. Temperature control for flask heater, distillation liquid in flask and column head.

Pilodist Filmdist SP 200

Thin film distilling apparatus: continuous feed up to 4 L/h, temperature up to 250°C, vacuum 0.01 mbar, cold trap.

Retsch SM 100

Cutting mill: particle size 0.1 – 1 mm

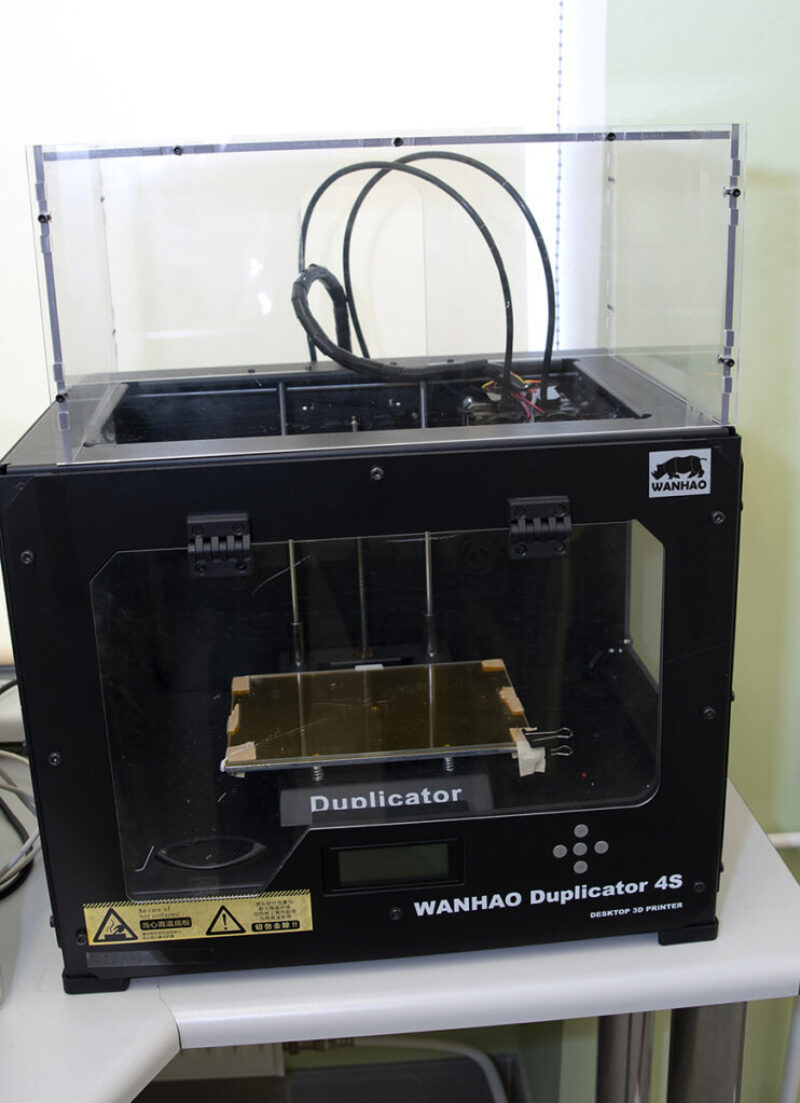

3D printing

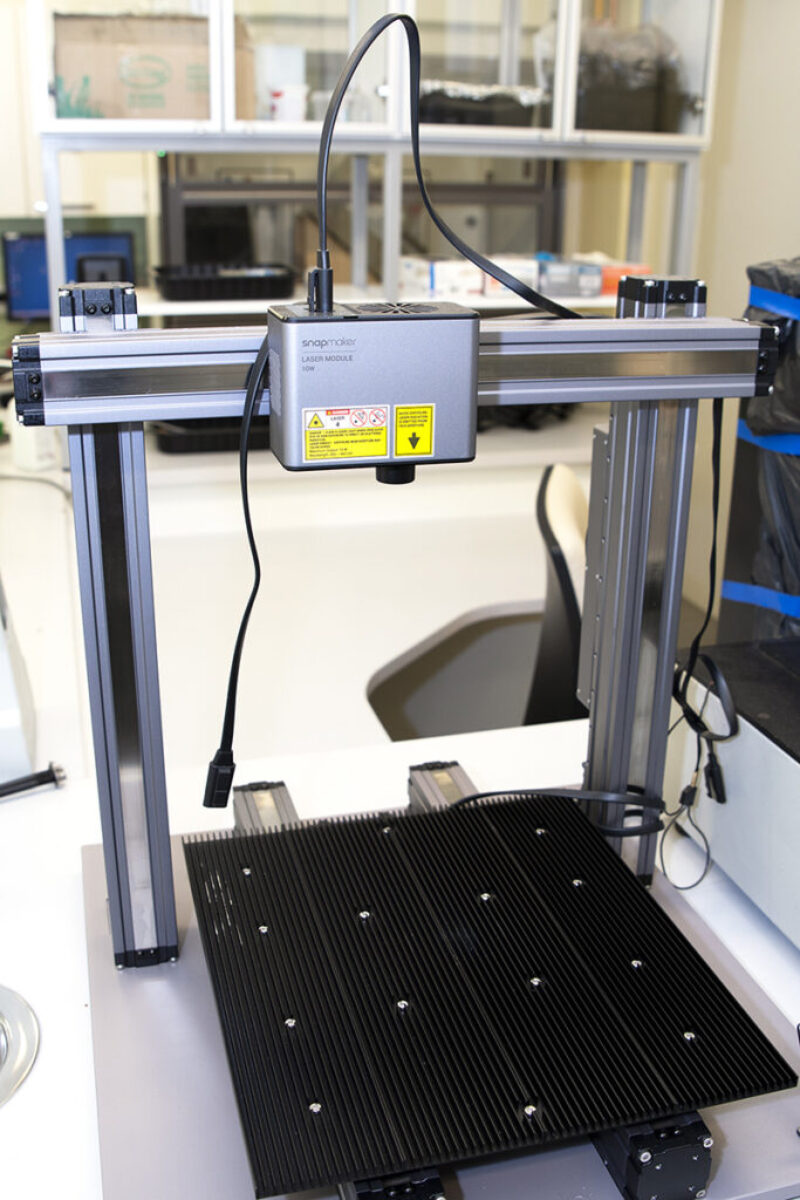

Laser cutting

Combined setup using HWS glassware

Laboratory reactor, 150 or 250 ml vessel, -20 — +200°C, up to 2 bar internal pressure.

Biopolümeeride tehnoloogia labor

Materjali- ja keskkonnatehnoloogia instituut

Tallinna Tehnikaülikool