Research

Outlined below are the primary research directions we are developing in our group currently.

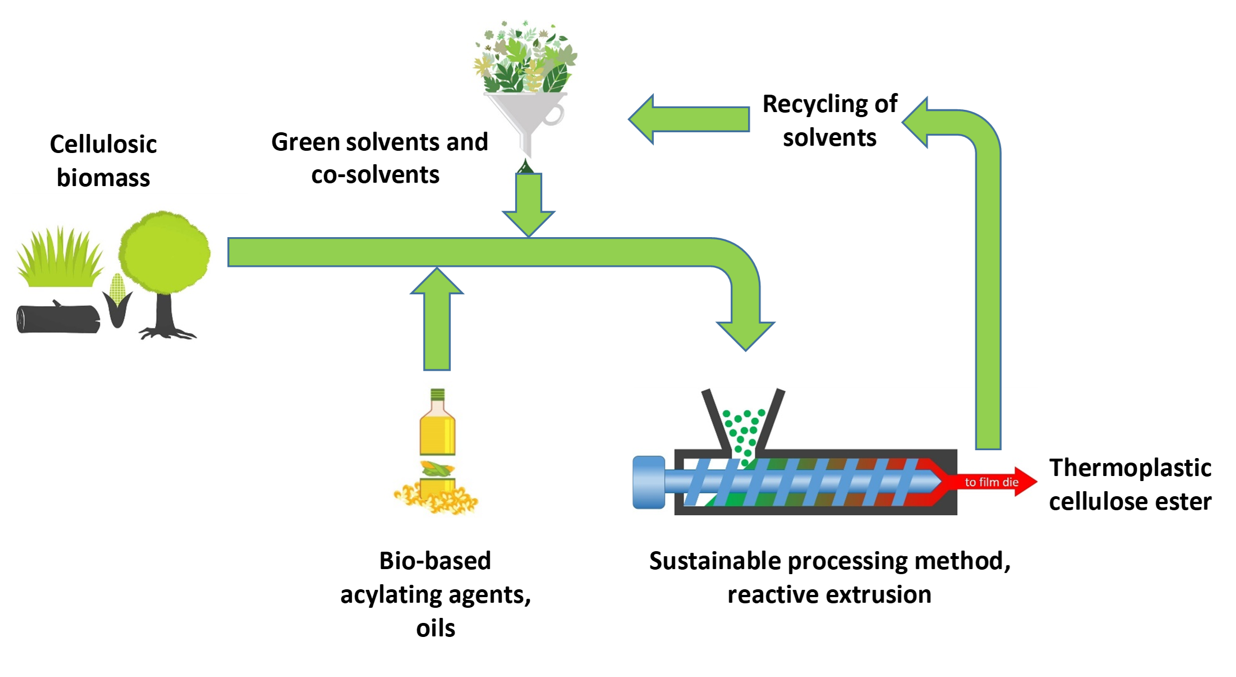

Thermoplastic cellulose derivatives to replace fossil-based plastics

Sustainable bioplastics are developed to replace non-enewable-resources-based materials in the plastics industry. Cellulose appears to be a nearly unlimited renewable resource for the bioplastics.

Innovative options for sustainable recovery of cellulose are being sought through the use of new, reusable solvent media, bio-based chemical modification reagents, and energy-saving technologies. The discovery of the dissolution processes of cellulose in ionic liquids opens several new routes for its chemical modification.

New, distillable ionic liquids are used as the reaction environment, and bio-based cosolvents are investigated to improve the sustainability of the solvent systems. Fully bio-based and nontoxic deep eutectic solvents are also investigated as alternatives for ionic liquids. Thermoplastic cellulose derivatives, fatty acid cellulose esters (FACEs) can be prepared without use of plasticizers, by attaching long-chain ester branches to the macromolecule of cellulose. Plant oil-based reagents are developed for cellulose esterification. The effect of the esterification reagents and solvent systems on rheology, crystallization behavior, morphology, and mechanical properties of the cellulosic bioplastics is investigated. A reactive extrusion technology based laboratory pilot line is started. The producing and processing parameters of the new bioplastics are clarified for further applications.

Reactive extrusion technology

Increasing reactivity of the plant oil based esterification reagents for synthesis of FACEs by mechanochemical action is a perspective research area intensively investigated in the laboratory.

The most promising mechanochemical method, where both high shearing and elongational forces are present is reactive extrusion (REX) in co-rotating twin-screw extruder. REX is known in general as a method in the area of polymer synthesis and modification, providing the highest yield with the shortest time and minimum usage of energy, solvents, and reactants. The extrusion process is continuous, having, therefore, good perspectives for industrial up-scaling. REX can process highly viscous substances; therefore, much higher cellulose concentrations can be expected than in a batch-wise stirred reactor, significantly reducing the need for solvents and co-solvents.

Several aspects of REX are investigated in combination for minimizing the energy and solvents consumption and maximizing processing rate: processing parameters, screw configuration, specific types of solvents and co-solvents, the chemical composition of the plant oil-based esterification reagents, activation of cellulose, etc. Recycling of the solvents and by-products is also investigated for reducing the environmental impact of the process.

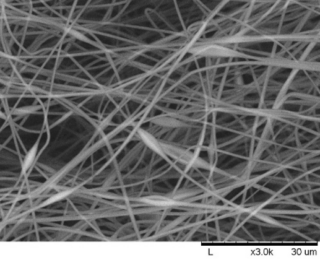

Advanced micro- and nano-fibrous materials for energy storage, energy harvesting and filtration of small particles

Electrospinning technology is applied to developing materials for energy storage or harvesting and for filtering materials. Biopolymers are used as matrices of sophisticated composites of electrospun nano- and microfibres.

The laboratory is the only one in Estonia capable of pilot production by electrospinning technology.

Fully electrospun, nanofibrous electrochemical double-layer (EDL) capacitors were developed, which are suitable for high-frequency applications without significant loss of capacitance under specific environmental conditions such as space missions. The aim was to achieve high EDL capacitance, long cycle life, and good mechanical properties from electrospun composite electrodes consisting of carbide-derived carbon (CDC) and polymeric matrix without further processing as carbonization. For this purpose, various combinations of polymer/solvent/carbon were tested in the electrospinning process. Furthermore, to improve the electrochemical properties of the electrospun electrodes a variety of organic, inorganic, and ionic-liquid-based electrolytes were tested. The supercapacitors were produced in the form of flexible and stackable thin sheets. This is useful for the most efficient usage of confined space of (micro)satellite or spacecraft and in traditional applications. The study was conducted in cooperation with Skeleton Technologies OÜ and ESA.

Cellulose has been shown to work as an efficient energy generator and harvesting material when exploiting the triboelectric phenomenon. This opens new advanced areas of applications of cellulose-based materials. The triboelectric energy harvesting field is rapidly developing and requires more knowledge to facilitate this technology transfer to new products. One of the main strategies for achieving high-power generation in triboelectric devices includes manufacturing micro- and nanostructures. Cellulose derivatives were prepared and nanofibrous non-woven materials were produced from them by electrospinning. The main physical properties of non-woven materials were determined. Project partner RISE constructed triboelectric devices from non-woven materials and evaluated their ability to produce electricity.

Using electrospinning technology, new antiseptic nanoparticles containing filtering materials for face masks were developed. KBFI, a partnering institution, selected the nanoparticles, and their antiviral properties were tested at the University of Tartu.

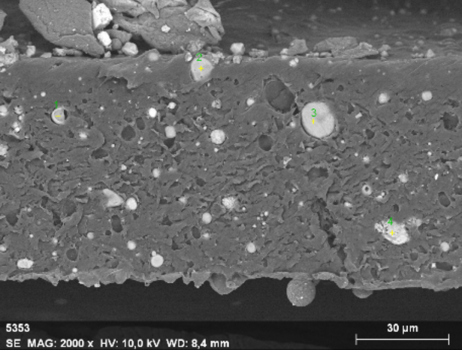

Sustainable plastic recycling, composites of waste plastics and secondary mineral or organic raw materials

The laboratory has a unique pilot production capability in Estonia in such important areas of polymer/plastics technology as compounding, extrusion, and injection moulding.

Composites of thermoplastic and thermosetting polymers with inorganic or bio-based additives are being developed to use secondary raw materials in the circular economy efficiently. In many cases, plastics require the use of mineral additives to affect the properties of the composite material (stiffness, thermal conductivity, fire resistance, etc.) and to reduce the proportion of plastic and, thus, the cost. It is clarified whether and how different mineral wastes, such as ash from electricity and oil production, can replace mined minerals such as limestone in composites. New knowledge is collected about the usage of the wood industry’s low-quality by-product, birch false heartwood, in the production of wood-polymer composites, thereby increasing the value of birch false heartwood and maximizing the outcome of quality birch wood. Solutions are also being sought for large-scale recycling of textile waste and lignocellulosic fibers as reinforcing fillers for plastic composites. All the studies contribute to circular economy by providing recycling options for local low-value or waste materials

Fully bio-based composites of lignocellulosic raw materials

Composites of commercially available bioplastics, such as PLA and thermoplastic starch, with components of lignocellulosic biomass, especially lignin, are developed. The physical and mechanical properties of the composites are investigated, and their processing capacities are verified in injection moulding and film blowing.

Biopolümeeride tehnoloogia labor

Materjali- ja keskkonnatehnoloogia instituut

Tallinna Tehnikaülikool